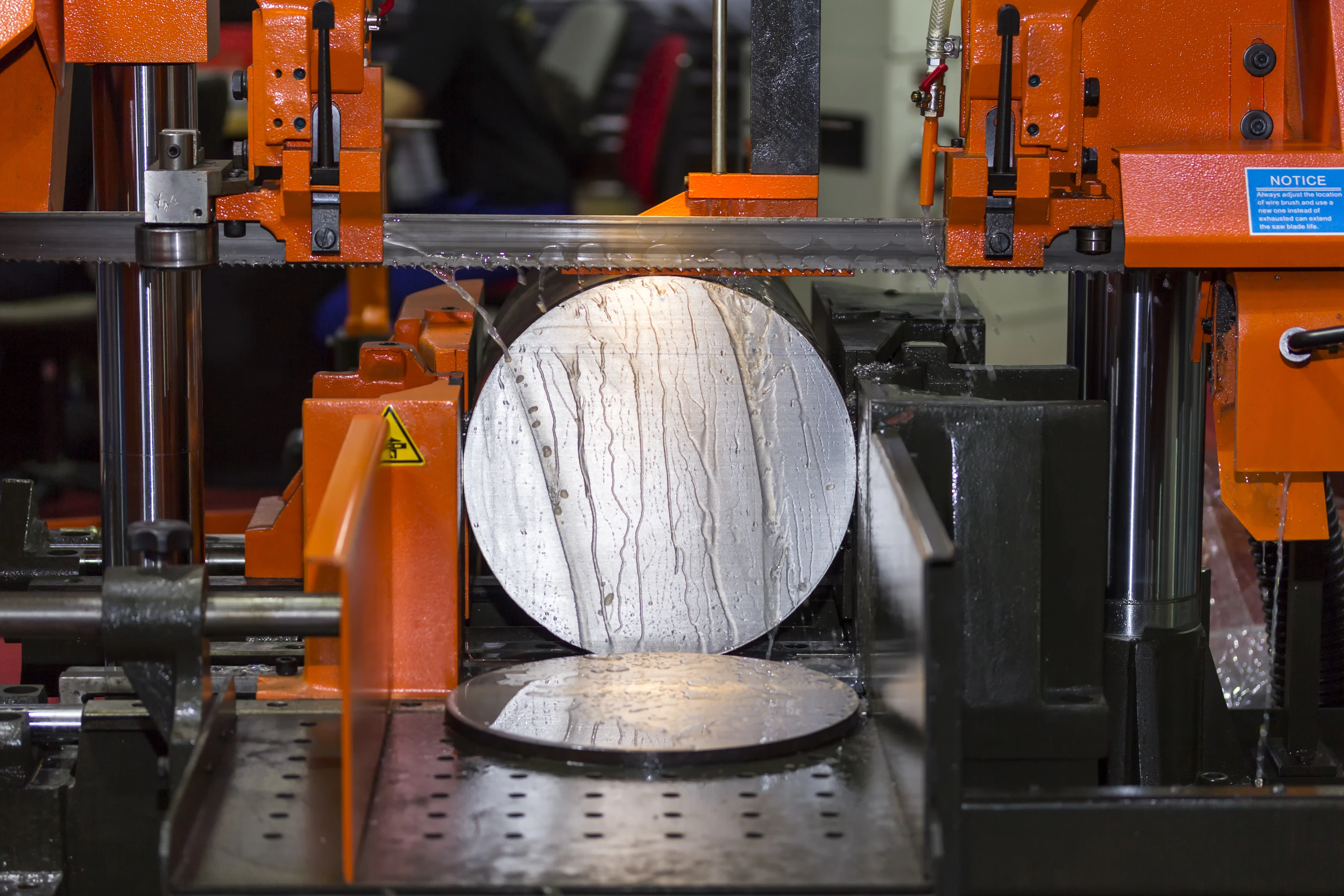

BANDSAW

Horizontal Bandsaw

- Throat size 84" tall and 50" wide

Mills

- 18" x 43" table

- 31.5x 16.0y 20.0z travels

- 20 tool carousel

- 2 1/2" spindle

- 48" x 60" rotary table

- 72.0x 40.0y 48.0z travels

- DRO

- 6" spindle

- 60" x 96" table

- 78.0x 52.0y 60.0z travels

- Tailstock

- DRO

- 12" x 52" table

- Power feed X,Y,Z

- DRO

Lathes

- 12" chuck at 16" swing

- 48" Centers

- 12 position tool post at live tooling - Turn, mill, drill, tap

- 48" chuck at 52" swing

- 60" Centers

- 8 position tool post

- 32" chuck at 44" swing

- 60" Centers

- 2 1/2" spindle

- 48" x 60" rotary table

- 72.0x 40.0y 48.0z travels

- DRO

Cranes

-

Overhead cranes from 3 ton to 50 ton

8

-

Jib cranes from 1/2 ton to 2 ton

5

Vibrator Stress Relieve

-

3 kW Allen-Bradley motor drive with external heat sink (80% heat dissipation is outside the NEMA 4-grade enclosure)

-

CNC control, via a 15” industrial touchscreen. The PC is “fanless” (runs cool / no fan needed) and has a solid state HD. Nothing mechanical on its die-cast aluminum chassis, for maxium ruggedness and reliability. VSR Treatments saved by printing as PDF (PDF maker installed at factory).

-

VSR Chart data includes plot of both workpiece amplitude AND motor power vs. vibrator RPM, the most useful data for the operator to fine-tune VSR Setups and process your parts quickly.

-

300 – 9000 RPM speed range vibrator, that develops a max 3200 lbs of force. Adjustable (takes 1 minute) unbalance over a 20:1 range allows wide range of workpieces to be VSR Processed with this system.

-

Speed regulation of less than 0.1% and adjustable frequency increment of 6 RPM.

-

Shown with mobile workstation with NEMA 4 enclosed disconnect switch, circuit breaker and 3 kVA isolation transformer.